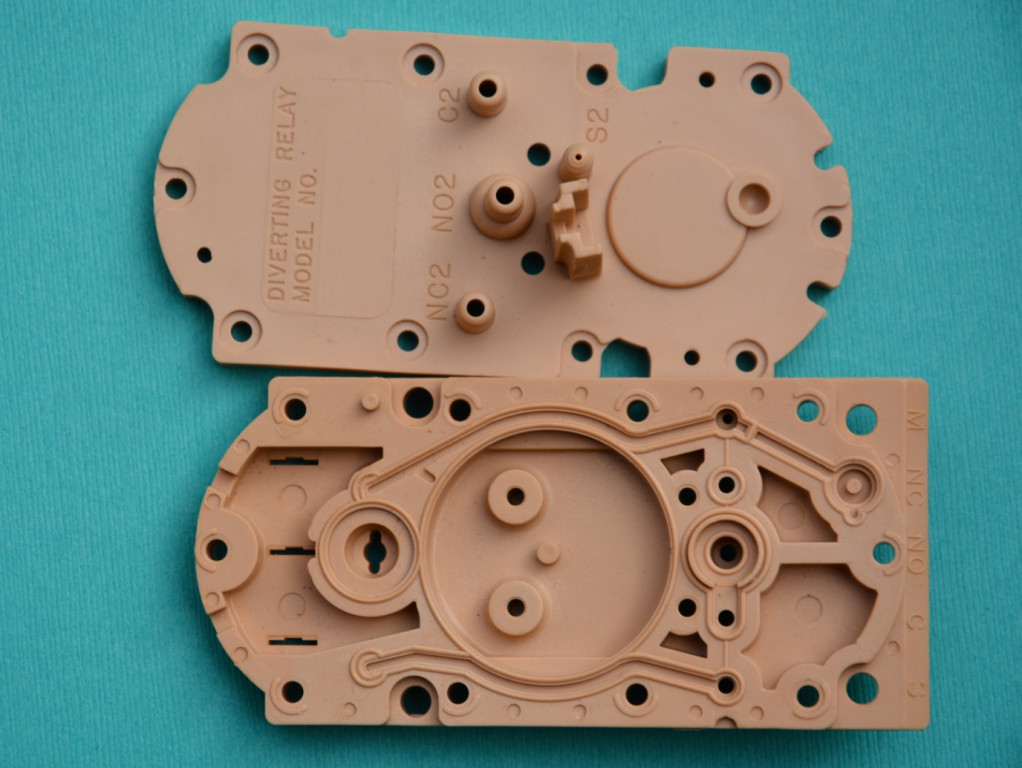

Injection molding manufacturing cuts across the production of automotive, food packaging, industrial to pharmaceutical products. With major plays like www.injectionmould.net and many others, it is of no doubt that this is a multi-billion dollar industry with many players. With 5000+ manufactures, it can be a drilling task to decide which Plastic Injection Molding Company to go by. The injection molding process is a challenging task and needs the best hand and brains at work. That is why we have prepared 5 key qualities to help you pick the best among many.

- Hire a Plastic Injection Molding Company with In-House Engineers

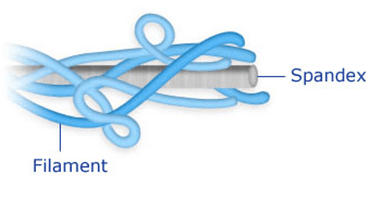

Having qualified and experienced in-house engineers should be your primary concern. With the many mushrooming plastic injection molding companies it is a fact some of them depend on day-to-day hiring of engineers when work pops up. If you need a quality molded product, go for a company with in-house engineers. Additionally, the company you choose must prove it’s engineers do attend occasional training programs. Such training help engineers polish their skill on injection molding resin selection as well as cheap but high-quality production techniques.

- Pick it that seems to Relate Well With You

For every business to succeed, the clientele relationship must be superb. Although a company might seem good in some aspect, if you do not seem to connect smoothly; that’s a red flag. A good clientele relationship is built on timely responsiveness, provision of a regular status update, and shared understanding. Does your chosen company listen to you or they seem to be of the “Know it all caliber?” For you to understand this better, consider asking for referrals from previous customers.

- Does your Preferred Plastic Injection Molding Company has Multiple Manufacturing facilities

There are several injecting molding advantages to accrue once you hire a professional Plastic Injection Molding Company. Professional company management understands that there are occasional accidents that occur in manufacturing plants. But that does not mean they do accept manufacturing progress halting whenever some machines fail. That is the reason why there is a need for extra manufacturing plants. Meaning, when one manufacturing plant fails, the injection molding process steps are shifted to another premise to avoid delays and delivery postponements which won’t augur well with you.

- Consider Checking every Plastic Injection Molding Company mode Of Business Operation

Consider working with a promising injection molding manufacturer. A promising company is one that can handle any manufacturing technique to cater for you molding needed of the day. Sometimes, you might need a different line of product. If the company you work with has a good operation mode, then it means they will take up the new challenge and save you the hustle for a new Plastic Injection Molding Company.

- How Good Is That Plastic Injection Molding Company in Product Designing

As you strive to keep up with the market dynamic changes, it means you will need to get creative. But without the help of an innovative company, you injection molding prototypes with not be impressive. The help of a good designing and innovative company will come in handy to ensure you figure out and create custom product designs that meet the current market needs.

Conclusion

Never work with a Plastic Injection Molding Company that does not harbor the qualities stipulated above. Remember, those qualities will determine your business success out there. Take your time and select a good company that will not disappoint you one bit.