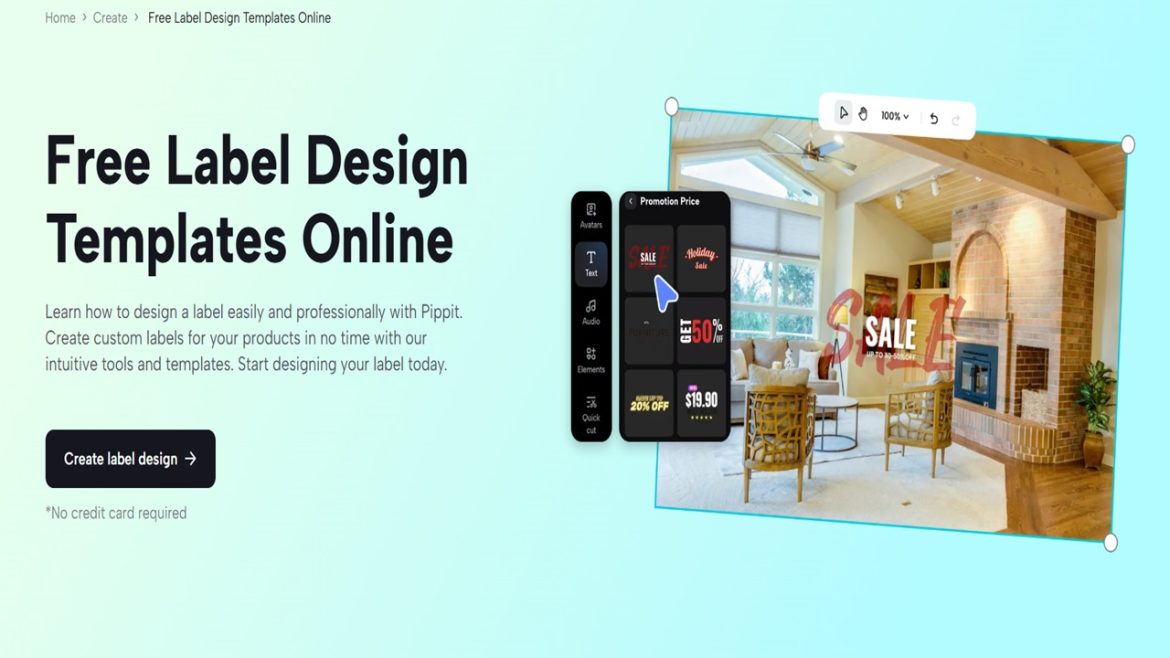

Every business needs to stand out from competitors when operating in a crowded marketplace. When customers encounter products in stores, the label serves as their initial brand encounter. Your product package represents more than just packaging materials, as it provides a valuable visual handshake that reveals quality, instills trust in customers, and validates your brand identity. Label design maker Pippit AI by CapCut, along with another digital tool, enables users to generate custom product labels that work more efficiently while saving time. The advanced tool allows businesses to use artificial intelligence to create powerful brand identities that maintain consistency across their entire brand presence. The implementation of custom product labels created through Pippit generates five essential methods to enhance your brand identity.

Instant Recognition Through Visual Consistency

Brand consistency stands as one of the fundamental elements that make branding successful. The visual presentation of your brand must appear consistent across all your marketing materials, such as social media profiles, as well as packaging and advertising. The Pippit label design feature supports business consistency because it provides adjustable standard template options that match specific brand fonts and color palettes. The AI-assisted functionalities on Pippit help businesses make brand-consistent labels according to their existing corporate assets. Through visual coherence, customers are able to identify your products right away, while your products develop recognition in their minds.

Professional-Looking Labels Without a Design Team

Businesses that lack professional graphic designer staff or creative teams must find alternative solutions for their labelling needs. The innovative solution, Pippit AI from CapCut, gives businesses transformative power. Users can produce high-quality professional label designs through a simple interface that operates in just minutes. Users can set guidelines for their label requirements by entering prompts into the AI system, which then aligns the design output. Users who lack design experience can still use available tools to adjust text elements and backgrounds, together with size and layout dimensions. Startups and small businesses can now achieve a professional presentation to their audience through this accessible solution, which creates an equal opportunity for all.

Specific Content Messages that Attract Specific Market

Customers can find direct communication through labels that they personalize, which becomes more than just an aesthetic addition. Through Pippit, users can develop product labels that address particular customer requirements for their beauty, food, fashion, or tech products. The design editor of Pippit lets you embed taglines and ingredient highlights as well as usage instructions and promotional messages that represent your brand identity. The individualized design approach found in this solution builds consumer brand rapport at product purchase time. Through its AI system, Pippit produces visuals and design choices that match both your product segment and customer profile, allowing you to achieve complete audience engagement.

Enhanced Brand Perception Through High-Quality Design

Customers judge product quality by examining the packaging quality. Labels that display thoughtful design elements showcase organizational professional competence, producing trusted brand imagery. Pippit AI delivers designs that are both visually appealing and ready for export at high resolution. Businesses can generate labels that adapt to any packaging requirement through the resize customization tool, which supports physical bottles and jars as well as boxes and digital product listings. Brands that use multiple sales platforms such as Shopify, Amazon, or TikTok Shop find value in this flexible design tool. The Pippit system preserves your brand quality across all platform interfaces, thus allowing you to achieve consistently strong brand presence throughout various platforms.

Faster Go-to-Market Time with Scalable Design Tools

Modern digital economics demands rapid operation in order to succeed. The AI label designer from Pippit speeds up design work by removing the requirement for manual layout development and design revision tasks. The adjustable design templates permit users to both reuse them directly and easily readapt them for new product or campaign requirements. Through its batch design feature, Pippit enables businesses to create multiple labels simultaneously, which reduces both time consumption and operational costs. Trading in this rapid design process allows businesses to swiftly handle market directions and operate seasonal marketing strategies, together with packaging updates. Together with fast label deployment, your business can secure market advantages that maintain contemporary and relevant product displays.

Conclusion

A product label functions beyond basic identification because it delivers crucial brand personality while maintaining your institution’s promises. Businesses can utilize innovative Pippit AI by CapCut tools to create personalized product labels that enhance both their brand perception and display an attractive appearance. Pippit serves brands by creating unique labels that strengthen brand-consumer connections through attractive design elements, which enhance both perception and operational speed, together with personalized messages. The time has arrived to advance your product displays. The Pippit label design tool enables businesses to create products through a tool that builds a powerful brand identity system that lasts in consumers’ memories.