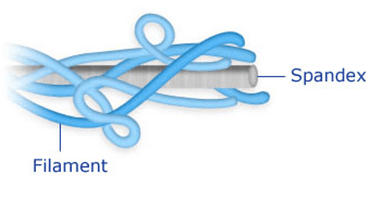

ACY is an acronym that stands for Air Covered Yarn; it’s made up of both spandex and DTY. Air covering refers to the combination of more than two yarns to come up with unique yarns that have different characteristics. One of the fabrics that are used is elastic while the other one is non-elastic. The main function of the non-elastic fabric is to improve the durability, evenness, aesthetics, as well as the functional properties of the fabric. ACY can be divided into two:

- Nylon ACY

- Polyester ACY

Companies such as Kabao Industrial Co., LTD specialize in the production of ACY that’s then used to make different types of clothes that are comfortable to wear such as socks, underwear, and swimwear. Air covered yarns have modified elasticity and can be designed for knitted, sewed, and woven fabrics depending on the properties.

The Effects of Air Pressure on ACY

During the production of air covered yarn, an elastic yarn such as lycra and a non-elastic yarn such as polyester are used. Polyester contains filaments that improve the abrasion resistance and uniformity in length for the ACY.

In the testing of the effects of air pressure on air covered yarn, elastic core spun yarns are used. Lycra is the core material inelastic yarn. The parameters of the air-covering machine are as follows:

- Delivery speed- 110 meters/min

- Air pressure- 4,6,8 kg/cm2

- Elastic draw ratio- 2

- Overfeed to jet %- 5

Here are some of the characteristics that are tested for in the air covered yarn:

- Denier of air covered yarn

The denier of the yard refers to the unit of measurement for the linear mass density of a fiber.

Denier of the filament was calculated after increasing the pressure from 4kg/cm2 to 8kg/cm2. It was observed that the denier of the yarn increased after increasing the pressure. The increase in denier is as a result of an increase in the bulkiness of the air covered yarn.

- Loop density

The number of loops in the yarn affect its properties and it’s, therefore, very important to measure the number of loops per 1m of yarn when it’s in a relaxed state.

After increasing the pressure, the loop density also increases. This can be attributed to the fact that the height of the loop changes as the air pressure changes; it results in an increase in the number of loops when the length of the yarn remains the same.

- Contents of the components in the yarn

To calculate the amount of lycra and polyester present in 1m of air covered yarn, take the sample and weigh it. After that, separate the lycra from the yarn and weigh the contents separately.

It’s observed that as the pressure increases, the lycra content decreases while the polyester content increases. One can safely conclude that the percentage of the lycra and the polyester varies depending on the pressure variations.

- Stability of the loop

After testing the effects of increasing pressure on the stability of the loops, it’s observed that the instability decreases as the air pressure increases. The decrease in instability caused an increase in loop stability. This is due to the increase in pressure at the binding point in the yarn which causes them to become much stronger hence the increased loop stability.

Conclusion

The process of air covering yarn involves the combination of two or more yarns and results in the formation of yarns with unique characteristics. These characteristics are affected when the air pressure is altered between 4 to 6 and 8 kg/cm2.

A change in the pressure has a significant effect on the yarn’s loop density, loop stability, denier of the yarn, as well as the lycra and polyester content. An increase in the pressure results in an increase in the denier of the yarn, polyester content, and loop density. It also results in a decrease in the lycra content and loop instability.