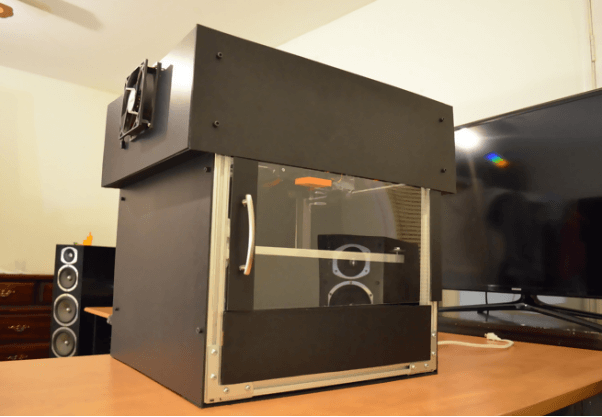

You have learned that 3D printing is also known as Additive Manufacturing. By definition, this is a computer-controlled layering of various materials with the need to create a variety of three-dimensional shapes. To be more precise, 3D printing is useful for the prototyping of materials and the manufacture of different geometrically complicated components. First developed in 1980, when it was a complex operation with few applications, construction 3D printers have become straight forward as well as affordable.

For that reason, this 3D printing solution has become useful for a broad range of uses. Some of the applications of construction 3D printers include product design, tool manufacture, aerospace engineering, and different medical applications. In this blog post, we shall analyze applications of construction 3D printer, including how it is impacting the industry. That said, the sales of construction 3D printers have risen since 2010. The domestic applications and uses of these machines have also become notable and practical.

The 3D printing system designed for construction is growing in demand. But how does it operate? You must comprehend the details.

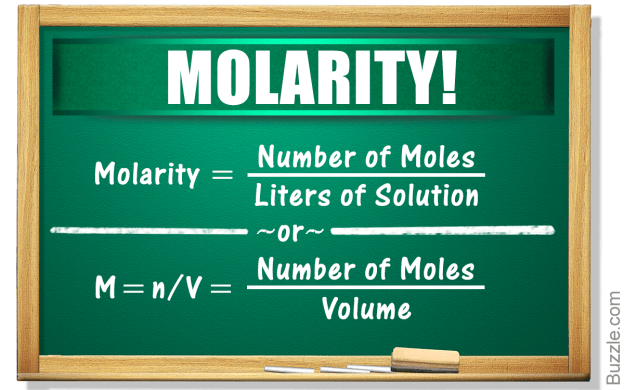

A 3D digital model of an item is often created using computer-supported designs where a scanner is also used. The printer should then read the design of the item you would like to create while laying down a variety of layers for printing. These materials can be powder or sheet where they get fused to create the end-product. While the process can be pretty much slow, it is efficient in creating any shape. And depending on the printing method used, 3D printing may produce several components at the same time. It can also utilize several materials and colors.

For those in the printing sector, accuracy can obviously be increased using a high-resolution process that successfully removes material from oversized printed items. A few printing methods can enhance the quality of the product include the utilization of various dissolvable materials that can support overhanging elements during fabrication. That said, materials like metal can be pretty expensive to print. For that reason, it can be cost-effective to mold printing.

A Look Into The Construction Industry

3D printing can be used to create various components that can be used in building in the construction sector. Construction is ideally suited to 3D printing, given the fact that the data needed to design and create a construction item will be generated through the modern design process. The industry is equipped with computer-aided manufacturing processes. And the emergence of different building information modeling can easily facilitate the rise in the application of 3D printing. Construction 3D printers can allow accurate construction of various complex items while cutting down labor costs.

Take-Home

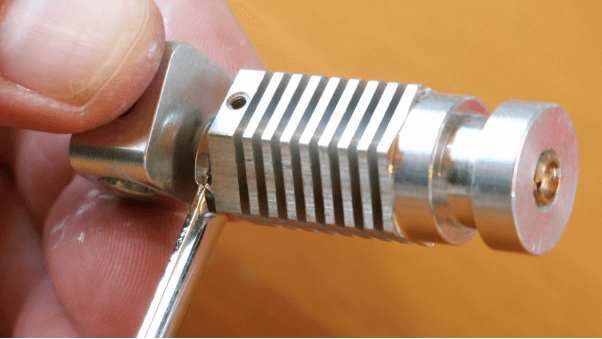

A construction 3D printer refers to a device that can build houses through depositing materials layer by layer. Usually, concrete 3D printing, which is also known as Construction 4.0, is similar to the FFF printing technologies. The concrete is pushed into a nozzle in order to print buildings.