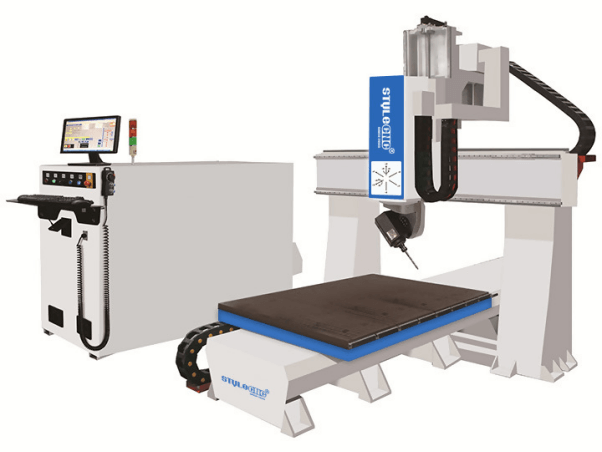

There is a significant rise in demand for the use of modern technology in different sectors. Most business professionals are also dwelling on the application of automation, which enables the use of 5- axis CNC Machining to reproduce voluminous quantities of high-quality units. Using a CNC Machine, you can also produce a better quality of products. In this article, we look at some of the common misconceptions of a 5-axis CNC in the manufacturing sector.

1. Expensive

For most business professionals delving into the world of machining using CNC, the cost is the primary element to look at. Such individuals can flee from investing in CNC machining without taking a proper look at the pros and cons based on the misconception that price is one of the most determining factors they must look at.

While it is vital to consider the price, it is also essential to understand that it is not costly to invest in this business. In fact, over the years, most people in the manufacturing sector have delved into the world of technology. This implies that they are determined to be part of the process. But, since CNC machining is pretty unique in its ways, the same people have been assuming that it is not affordable. Well, in this article, we have highlighted the fact- CNC machining is affordable.

2. Everyone Is In A Position To Run A 5-axis CNC Machine

This is one of the most bizarre beliefs most professionals in the tech sector hold onto. To be honest, not everyone can run a CNC machine. To drive this point home, we have decided to explore the uses of the device in different sectors. For starters, it can be utilized in evaluating as well as replacing dull tools in a facility. For an individual to achieve this, they need to have a clear comprehension of the uses of a CNC machine.

In most cases, it takes a professional to run it. That is why it would be wrong to assume that everyone can run it. But, while at it, you also need to be aware that with a training session, just about anyone can efficiently operate the machine.

3. The Code Should Not Be A Big Deal

All too often, people have held to the belief that CNC machining, regardless of the type, is controlled using a computer. However, this is not true. Even though computers play a role in the operation of a CNC machine, it still relies on certain controlling aspects such as a G-code in addition to a trained mechanic who can operate the machine. The modifications must also fit into the device.

Take-Home

CNC machining entails an extensive process used to control machining tools such as 3D Printers. Usually, a computer is used to manage the entire process. Since there are different types of CNC machining, you need to be familiar with their uses and applications in the sector you serve.