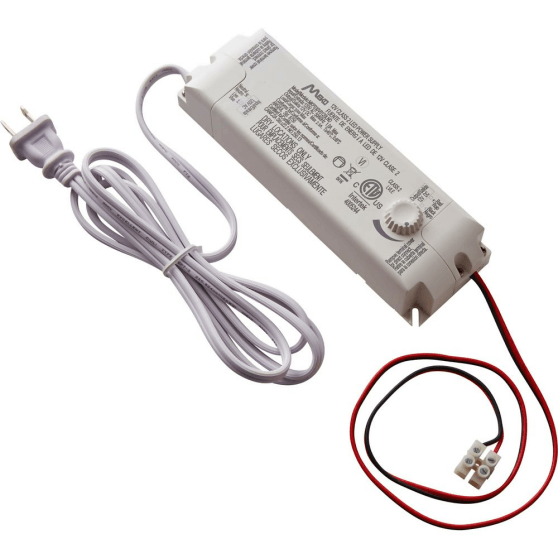

As a result of technology advancement in the lighting field, you can now fix an LED dimming power supply in your house or office to help you regulate the amount of light produced in a bulb. Due to various benefits that lone is likely to enjoy by fixing the unit in question, most people have embraced it. In this article, some of the prevalent advantages of using LED lamp dimmers will be discussed.

- They are energy saving

Unlike some of the traditional LED power supplies, LED lamp dimmer helps you save the amount of energy used since you have the control power for the amount of light produced. As a result, you can reduce the amount of light while not actively using it, thus helping you to consume lesser energy. Consequently, it lowers the maintenance cost, hence making it more affordable.

- Extended lamp lifespan

Additionally, dimmable led light fixtures have a longer lifespan compared to other units. The fixtures in question are more likely to last longer, mostly when used while dimmed. Dimming the lamp makes it run cooler, thus extending its lifespan as well as that of an LED driver.

- They enhance ambiance

The primary advantage of an LED dimmer is to allow the user to regulate the amount of light produced. A brighter light is essential when working or performing an active task. However, a lesser intense light enables you to relax better. Consequently, an LED light driver lets you to experience the ambiance in question.

- Easy to fix and control

Besides, the LED light in question is easier to control and use. With only LED drivers’ basics, you can be able to adjust and use it, hence experiencing the fantastic ambiance. However, with simple instructions, anyone can be able to control and regulate the unit.

- They have increased visual task performance

Also, dimmer led can be used for more than one task performance, thus making it more effective and economical. For instance, it can be used to produce an intense light and a dim light as well. As a result, the light in question becomes more useful compared to other lights whose intensity cannot be regulated.

- Cost-effective

Comparatively, an LED dimming power supply is more cost-effective compared to other types of lighting units. For example, dimmable led driver 12v is relatively cheap, lasts longer, and consumes lesser energy than the other LED driver 12v units. Therefore, the dimmable unit, you can save more since you will need lesser replacements, and also you will consume lesser energy, thus paying a lower bill.

In conclusion,

As discussed above, there are various advantages associated with an LED lamp dimmer. Cost-effectiveness, increased visual task performance, easy control, enhanced ambiance, extended lifespan, and energy saving are some of the main benefits. Therefore, if you would like to enjoy the benefits in question, among many more, consider installing an LED dimming power supply unit.