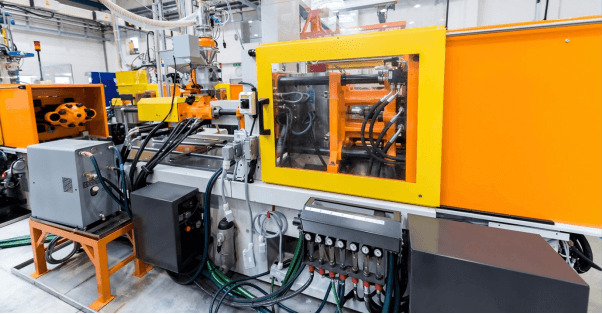

Injection molding is a prominent manufacturing process used in producing different parts literally by injecting some molten material into a piece of mold. Usually, injection molding can easily be performed using a variety of host materials including metals, glasses, as well as elastomers. The raw material used will be fitted into a barrel and then mixed and injected into the mold cavity. Since the process is involving, professionals and emerging manufacturers need to understand the basics of injection molding design.

- Advanced Technology For Injection Molding

Plastic is a material primarily used in almost every aspect of production in the manufacturing industry. Plastic is basically available in nearly every part of the world. It is often used in the manufacture of cell phones and other related products. For that reason, manufacturers need to understand the basics of incorporating advanced technology in injection molding. In this case, a sophisticated machine is used in creating plastic materials.

2. The History Of Plastic Injection Molding – Its Evolution

The industry of plastic injection molding has been evolving since 1870. The business is developing into an international docket comprising of different plastic inventors, manufacturers, and retailers. To support emerging entrepreneurs, pioneers of the industry have been creating relatively affordable products.

3. Thermoplastic Injection Molding

Thermoplastic injection molding refers to a unique manufacturing process known for creating fully functional parts using injection plastic resin. Usually, the resin is injected into the pre-mold material. Notably, thermoplastic injection molding is broken down into different categories, including rapid injection molding and production injection molding. Both methods utilize a particular temperature to create plastic material.

4. Understanding The Process Of Over molding

A plastic over-molding injection is typically a two-shot process that creates one product by combining two primary separate complimentary thermoplastic materials. Overmolding is also used to create an original soft grip. This implies that pulling occurs from the primary source of raw materials. Plastic material is then selected and used to spearhead the flow while maintaining the chemical resistance.

5. A Look At Hot Rubber Molds

Rubber molding plastic injection refers to a significant process that usually produces a usable rubber product. Rubber products are manufactured through this process. On the other hand, an elastomer can also be used. It is a material with enough resilience to return to its initial shape in response to the pressure it has been subjected to. Hot rubber molds are often used in heating melted plastic resin. After that, the products will be sent to the opening of a gate to fill some form of the mold cavity.

6. Injection Blow Molding Process

Blow molding is slightly similar to extrusion molding. However, it uses a metal shank in product creation and, finally, delivery. Its parison contains a fully formed neck coupled with a thick tube that has a polymer attached to the body.

Take-Home

Injection mold processes take advantage of the pressure exerted on the raw material to create products. The process is used to come up with various products such as glass and plastic. As indicated in this manuscript, all these methods are essential in the development of products.