Electronic prototyping is the creation of a user interface that is similar and acts like it has been completely coded and executed. Electronic prototypes look and feel very responsive, hence are the best candidates for assessment of detailed interfaces, page layout and direction finding.

After agreement on the functionality and overall flow then electronic prototyping is approved. Electronic prototyping is usually the next step in paper prototyping. When the electronic prototype is complete it is given to participants to test if they perform the required task.

Most of the electronic prototyping designers should possess skills such as programming, soldering, circuit designing, and wiring. This is to enable them prototype products that integrate hardware and form the best designs that when applicable they form a quality technology product.

Dan O’Sullivan and Tom Igoe are considered to have laid the way for electronic prototyping by the book they wrote on Physical Computing. In Italy some professors and students came up with Arduino Platform, these were to make electronics much simpler for electronic prototyping designers.

Electronic prototyping is a major contributor to the development and manufacturing a large number of products and services that make up the largest end-user products in the market.

Importance of Electronic Prototyping

Electronic prototyping can show and permit for tests and fine-tune on a number of features of your electronic product such as;

- Efficient design elements for a better electronic product.

- The simplicity or difficulty of developing a product with a particular plan.

- Outer look of the casing.

- Interior layout of the product, as well as how and where wiring and additional electronic features will be set.

Procedures for Electronic Prototyping

For a better electronic device, a good design should have been made. This is made possible electronic prototyping. The following are the procedures for electronic prototyping;

Pre-Design Your Product

In electronic prototyping like other of methods of prototyping, pre-designing is essential. For proper budgeting, I highly recommend you to pre-design your product before implementing the idea into a reality.

Electronic prototyping pre-design will help you determine the correct number of products you will manufacture so as to reduce the cost of manufacturing. Most developers and entrepreneurs usually skip these procedure landing them into losses, but if they were to pre-design there products it would be cheaper and could have made more profits.

Having a clue on the production cost really helps, hence created a predictable hardware report. The report consists of an initial design for an electronic prototype design of your product. It also has precise estimations on the cost of development, scaling, and manufacturing of the product. Another thing is not building castles on the profits you may get, companies such as Apple, Microsoft or Samsung do not estimate their profits before. Hence you should not have estimates of your electronic prototype profits.

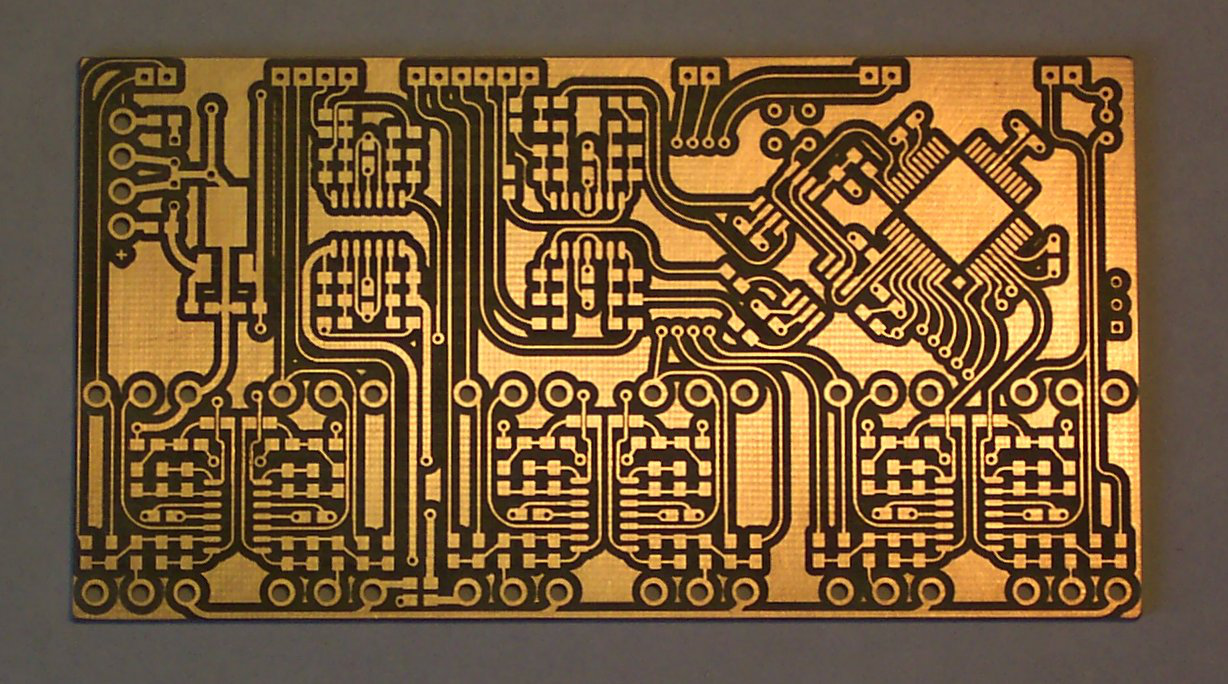

Electronic Prototype Representation and Printed Circuit Board Design

For an ideal electronic prototype, you should come up with a representation and PCB design facilities. This electronic design is also known as a schematic diagram that is related to a house blueprint. It is always advisable that you have a schematic diagram for every part of your system. The representation has every feature, from microchips to meek resistors, and connects.

To create a representation of an electronic prototype you are needed to use a special electronic design software. DipTrace is the highly recommended software in designing of electronic prototypes and it is simple to use. If you are an upcoming designer I strongly advise you to use DipTrace due to its affordability.

Once you are complete creating the electronic prototype representation, you will start designing the definite Printed Circuit Board. Many designers find difficulty in creating a printed circuit board layout is usually tiresome and time-consuming. Hence designing of the printed circuit board is done by the same software used to create the electronic prototype representation. The software ensures that the printed circuit board design adheres to all the design rules and should be similar to the representation.

If your electronic prototype product is small, then the tighter the components must be together and the more time it will consume to come up with the printed circuit board layout. For the wireless or large power consuming products, the layout becomes more critical. Many printed circuit board designs the most crucial part are the power channeling, wireless circuits, and any high-speed signals.

Bill of Material, Printed Circuit Prototypes, Evaluation, and Programming

During the creation of an electronic prototype, there should be the generation of how much cost will the manufacturer incur? Bill of material lists the quantity, component specifications and the part number required.

After designing the printed circuit board design, then your software will allow you to output it in a Gerber format with a single file for each layer. The Gerber files are taken to a prototype shop for small capacity runs or can be taken to vast manufacturers for high volume manufacture. Reaching the manufacturers or the prototyping shops, then all the electronic components are fused onto a board.

When assembling the boards I highly endorse the use of SeedStudio Fusion. They have very affordable prices on quantities from five to eight thousand boards and also offer three-dimensional printing facilities.

Also for printed board designs, I recommend San Francisco Circuits and Sunstone Circuits as alternatives in the electronic prototyping of your printed circuit boards. For a fully assembled boards, it takes between one to two weeks. Advanced printed board circuit methods are there but at high costs.

For many electronic prototypes, evaluation is necessary this is because most do not work perfectly from the start. You have to go through numerous repetitions before finalizing the scheme. In this step, you have to notice, debug and fix arising issues with your electronic prototype. This stage is usually costly and takes a lot of time.

The next stage after an evaluation is programming the microcontroller unit. A microcontroller acts as the brain of the electronic product. It is very tiny and is same to a microprocessor. Programming of the microcontroller is so essential for the product to perform its required function. The firmware program is permanently put in storage in the microcontroller memory but it is programmable.

Accreditation

For every electronic product sold they must numerous categories of certifications. Certifications differ contingent on which country the product will be sold. These enables the company to know how many devices are sold to a certain country.