For most of you, searching for 3D programs is a difficulty. This list appeals for all the programming for all your 3D printing requirements: from 3D displaying to cutting, from a beginner to an expert. Get down to the area that you are most keen on: the 3D Modeling Tools segment covers all sort of CAD programming, the Slicers and 3D Printer Hosts segment contains the most recent print planning applications and to wrap things up, the Other Handy Tools contains programming that may prove to be useful while repairing a 3D display.

3D Modeling Tools

There are three fundamental classifications:

- CAD Tools

- Freeform Modeling Tools

- Sculpting Tools

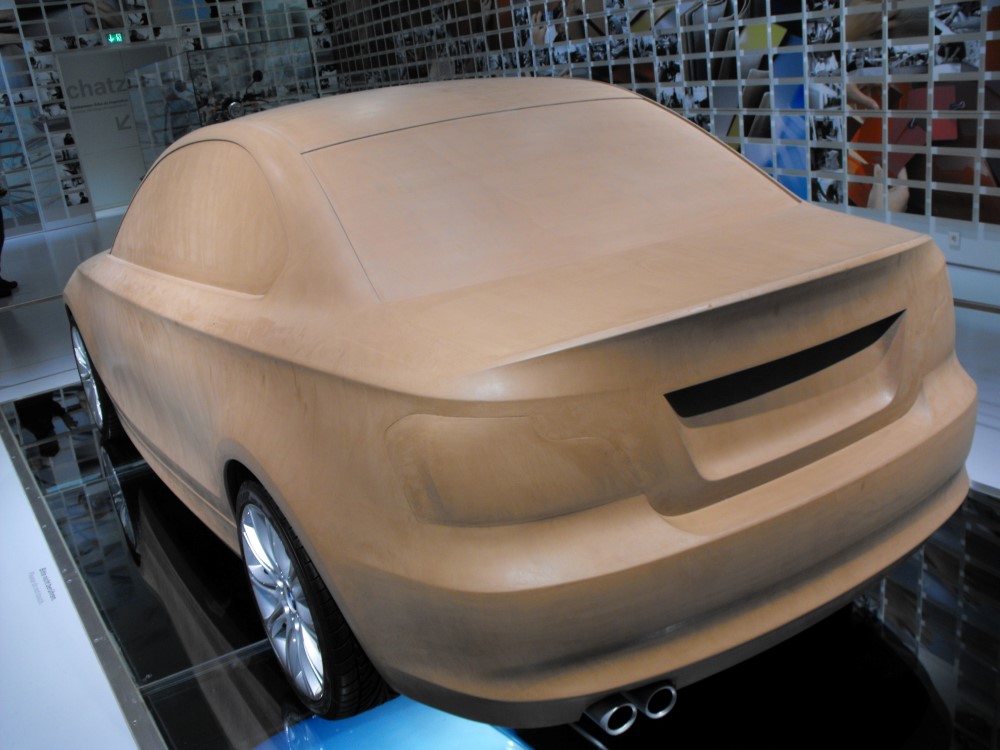

Though the apparatuses of every class can produce models appropriate for 3D printing, the way the sources of info are produced are extraordinary: CAD devices are to a great extent in light of utilizing geometrical shapes to construct models while freeform demonstrating instruments enable more opportunity by enabling you to make freestyle shapes. Chiseling instruments are essentially similar to utilizing advanced dirt that you can push, force, squeeze and get to frame your models.

Computer aided design Tools

- FreeCAD. This is a parametric 3D modeler worked for item outline and designing. Highlight rich and with a high expectation to learn and adapt, FreeCAD is fairly for cutting edge clients. The product is multi-stage, and runs perfectly on Windows and Linux/Unix and Mac OSX.

- Geomagic Design. Geomagic Design is a far reaching and hearty mechanical CAD configuration instruments, enabling plans to go from idea to generation for proficient specialists, producers, understudies and specialists. Geomagic Design is accessible in three forms: Personal, Professional and Expert, each custom fitted to the requirements and spending plans of the individual client base.

- Inventor. Inventor 3D CAD programming deals with a simple to-utilize set of tools for 3D mechanical framework, documentation and item reproduction.

- Producers Empire. Producers Empire 3D is anything but difficult to utilize 3D outline and printing programming. It is worked to be usable by kids as youthful as 5. The paid variant incorporates an essential/primary school learning program; teacher’s Dashboard, asset, educational modules and expert advancement. It keeps running on: iPad/iPhone/Android/Mac/Win/Chrome book.

- Morphi App. Morphi is a straightforward, effective 3D outline application right now accessible for iPad and Mac. Morphi involves those of all ability stages to make 3D models from anywhere with touch, on the web or disconnected, utilizing 3D figures, content, hand drawing, high complexity pictures, and streamlined 3D demonstrating apparatuses.

- Rhino 3D. Rhinoceros is a solitary, business NURBS-based 3D displaying programming normally utilized for mechanical outline, engineering, marine plan, gems plan, CAD/CAM and quick prototyping. Rhino’s prevalence depends on its decent variety, low expectation to absorb information, generally ease, and its capacity to import and fare more than 30 record groups, which enables it to go about as a ‘converter’ apparatus between programs in an outline work process.

- SketchUp. SketchUp is a 3D displaying program for applications, for example, building, inside outline, common and mechanical designing. Its effective yet simple to utilize interface make it perfect for apprentices in 3D demonstrating. A freeware adaptation, SketchUp Make, and a paid rendition with extra usefulness, SketchUp Pro, are accessible. Note that the free form does not enable you to fare for 3D printing, you’ll have to introduce a module to do as such.

- Solidworks. SolidWorks is a 3D mechanical CAD program broadly utilized among specialists and creators. The product includes effective recreation, movement, and plan approval devices, propelled wire and pipe directing usefulness, figuring out capacities, and that’s only the tip of the iceberg.

- TinkerCAD. TinkerCAD is a software package based 3D exhibiting program seamless for amateurs. You can spare your strategies on the web or offer them with others. Fare documents to print with your own particular 3D printer or send your plans to one of famous 3D printing administrations.

- Vectary: This is a free, accessible 3D displaying gadget and group stage where you can make, share, and tweak 3D prototypes. The Free Plan offers you a very utilitarian and simple to-utilize toolset, with boundless open prototypes to make and share, and a predetermined number of private models.

- 123D Design. 123D Design is an effective, yet straightforward 3D creation and altering device. The free form gives you access to most highlights and enables you to make and utilize 3D models for non-business purposes.

Slicers and 3D Printer Hosts

If you are looking to print and execute a 3D print, you will need:

- Ultimaker Cura. This Ultimaker Free slicer and host software is an open source; not limited to Ultimaker 3D printers. If you are a novice, this offset lithography software suits your naïve’ starting needs for it gives a superb 3D printer front end.

- ReplicatorG

- Repetier Host

3D Imprinting in Aviation

The avionic business incorporates a scope of business, modern and military applications, and is contained divisions that outline, make, work and keep up the airplane or rocket. Among the principal supporters of 3D printing, the carrier business is a main impetus in the development of this innovation for both assembling end-utilize parts and prototyping.

-

3D Printing for Business Flying machines; the Airbus

As per Peak, one of the flight business’ best pioneers, Airbus, now has a record number of 3D printed parts on their new A350 XWB air ship, with 1,000+ sections. Cooperating with Stratasys helped them create these parts rapidly and effectively utilizing elite FDM materials like ULTEM 9085. This creation review thermoplastic is a solid and FST consistent material with phenomenal quality to-weight proportion, ensured to Airbus’ determinations.

-

3D Printing for Modern NASA Shuttles

Essentially, an article by Robert Dehue additionally clarifies that NASA is utilizing a Stratasys 3D printer to create and test a space wanderer. The meanderer is about the span of a Hummer with a pressurized lodge to help life on Mars and at present contains more than 70 FDM 3D printed parts.

The 3D printed parts on NASA’s meanderer incorporate fire resistant vents and lodgings, camera mounts, unit entryways, an expansive part that capacities as a front guard and numerous other modified apparatuses.

As though 3D imprinting on the ground isn’t cutting edge enough, added substance innovations are likewise being tried in space. 3D technology at a development scale will have a wide assortment of uses inside the private, business, mechanical and open divisions.