Inkjet machine and HeatSign laser marking machine are both commonly used today for engraving. However, laser engraving machines have become accessible and cost-effective because they do not require the use of ink and bit head that need to be replaced over time and therefore may replace inkjet marking machines in the long-run.

Nonetheless, before you decide what to purchase for your purposes, it is essential to understand the differences between inkjet and laser marking technology.

Material and application

Inkjet marker

For each application, the ink in the inkjet marker is optimized to provide the best adherence. The technique can be used for marking metals, plastics, and ceramics.

Laser marking machine

The process of using a laser is versatile. It can be adapted to various marking activities because of its ability to adjust. For example, the wavelength and speed diameter of a beam can increase or decrease depending on the surface it is intended to mark. It makes it possible to use on hospital equipment and auto motives.

Types of marking

Inkjet marking

It can be used to mark 1D and 2D patterns of a serial, model number, barcodes, and logos. However, its low resolution limits it from marking tiny logos and barcodes.

Laser Marking

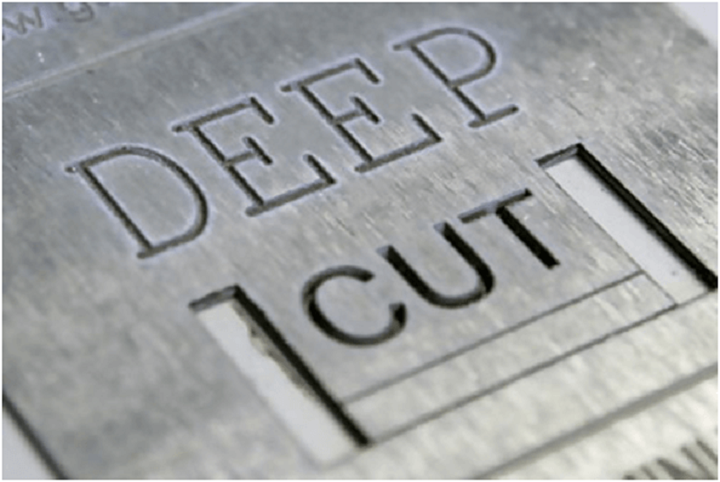

The micrometric size of its beam makes it possible to mark the smallest of logos and barcodes. Such can be a reason that makes laser engraving machines best for use in any application.

Technologies basis

Inkjet machines

There are two types of inkjet machines, the continuous inkjet marker (CIJ) and the drop on demand inkjet (DOD) marker. The CIJ drops ink continuously on the surface being marked without touching that surface while the DOD marker keeps ink in its nozzles and when it is turned on, it drops ink onto the surface to be marked. It makes better marks than CIJ but has to be close to the surface that it is modifying.

Laser machines

Laser engraving machines differs depending on the material to be marked. But, the technology behind the marking is the same only that some elements are hard to label and others are not. When the laser beam is moved to the surface to be engraved, the energy moves to that point, making a permanent modification to the surface.

Performance and cost

Inkjet marking machines

Inkjet machines can mark a wide range of materials using different colors, and therefore, it is relatively cheap. However, the operational cost is high because of the utilization of ink. Additionally, the ink contains harmful chemicals which raises health and environmental issues. Also, as the ink dries on the marked surface, it does not assure permanent marking, especially in harsh conditions.

Laser engraving machines

Laser marking machines, for example, fiber laser marking machines, does not require consumable parts of electricity. They do not require high maintenance and has a long lifetime making them economical and an option for a large amount of work.

Additionally, the beam size enhances the capability of marking densely and making small modifications, ensuring that the marks are permanent.

Which technology fits your purpose?

Inkjet has low purchasing price but high recurring operational cost. However, it can be used on various materials and multiple industries. Unfortunately, its markings are not permanent and can deteriorate in harsh conditions.

On the other hand, laser engraving machines are relatively expensive but convenient. Its markings are permanent, and they don’t deteriorate over time.

You need to understand the types of laser marking machines, their application, and how they work before you purchase any for your industry. The following are the common types of laser engravers.

- 1. CO2 Laser

The CO2 laser is used to make a permanent marking on nonmetal material. It uses carbon dioxide, hydrogen, xenon, nitrogen, and helium. The mixture of these gasses is emitted via discharge tube and together with light refracted through several mirrors in the laser, mounts an engraving on the surface. So, if you need an engraving on plastics, stones, wood, paper or rubber CO2 laser is the best option.

- 2. UV Laser

This type of laser is best if your products are delicate, for example, thin latex. Additionally, it can achieve high quality marking on silver and gold material.

- 3. Fiber laser

Fiber laser marking machine is commonly used for engraving on metals. However, it can be used to engrave on other materials too. Also, the fiber laser engraver is convenient for any delicate materials; for example, a handheld fiber laser marking machine can be used to engrave logos on cups and watches.

Another advantage of fiber laser machine is its ability to mark the hard to reach parts of a package. Therefore it is a good investment for the food and beverage industry. Additionally, they are energy efficient and does not require high maintenance.

Generally, the laser marking machine is better in comparison to inkjet. However, you need to ask some questions before you settle to buying a laser engraver.

- a. The material you are coding onto

Laser marking machine can be used to encrypt on glass, wood, and any material. The engraving is precise no matter what size of the font is used.

- b. High quality

Have you seen wine bottles? The quality of the engraving is high and cannot be distorted no matter what conditions. Therefore, if you are looking to have the best quality or well-presented engraving design, choose a laser engraver machine.

- c. The speed for running your production

Laser marker machine is efficiently fast and can return production benefit faster as compared to an inkjet. If you produce 100 products in a minute, the return on investment can be less than three years. Remember you don’t have to replace any component of the laser in those three years; therefore, it is cost effective.

- d. Start-up capital and ownership cost

Laser engraving machine price is decreasing over time. Therefore, even the small scale users can have laser machines. Nonetheless, you can look out for sites that sell used engraving machine, which is a cheaper option, and it minimizes your startup cost.

Take away

Laser technology is replacing the traditional mechanical engraving, and depending on your need, suppliers are providing small engraving machines, handheld laser marker, and any laser you need. Above all, research on the type of lasers available in the market before you invest your money.