Rapid prototyping has revolutionized the way products are developed and brought to market. By enabling quick and cost-effective production of prototypes, this technology has empowered innovators and businesses to iterate, test, and refine their designs easily. Among the significant contributors to the advancement of rapid prototyping are cnc services from china, which have played a crucial role in driving efficiency and accessibility in the prototyping industry. As we look into the future, several emerging technologies and applications promise to transform further and shape the landscape of rapid prototyping.

Additive Manufacturing

Additive Manufacturing (AM), commonly known as 3D printing, has already made its mark in rapid prototyping. However, its future holds even greater promise. Advancements in materials science, including biocompatible and conductive materials, will broaden the scope of applications for additive manufacturing. It includes everything from biomedical implants and wearable electronics to aerospace components and architectural structures. The ability to print with multiple materials in a single process will also become more prevalent, allowing for complex and functional prototypes that closely mimic the properties of the final product.

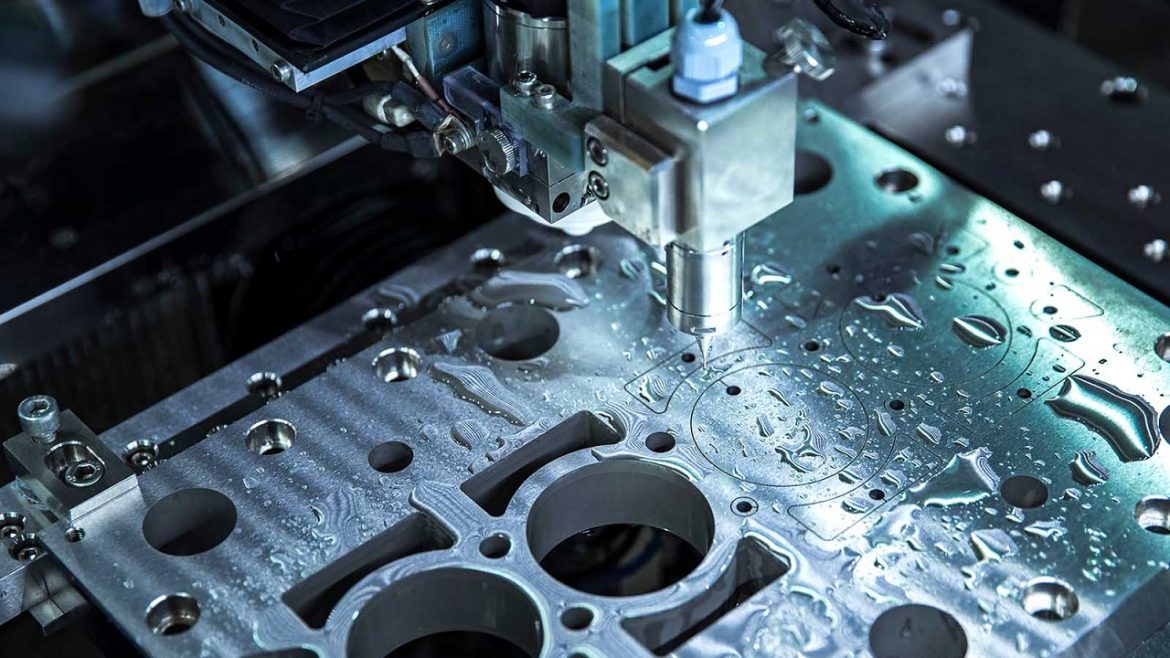

Smarter and Faster CNC Machining

While 3D printing garners significant attention, CNC machining remains a vital rapid prototyping technique. The future of CNC services from China and elsewhere lies in smarter and faster machines. AI-driven CNC systems will optimize tool paths, reduce material waste, and enhance precision. Furthermore, advancements in multi-axis and hybrid approaches, such as combining 3D printing and CNC machining in a single setup, will enable more intricate and accurate prototypes.

Integrated Software Solutions

The future of rapid prototyping will see a seamless integration of various software tools used in the design and production process. From Computer-Aided Design (CAD) software to simulation and slicing programs for 3D printing, a unified platform will streamline the workflow. This integration will enable designers to visualize and simulate their prototypes more effectively, leading to better-informed decisions before manufacturing.

Rapid Prototyping for Electronics

Electronics prototyping has traditionally lagged in terms of speed and accessibility. However, advancements in printable electronics and conductive inks are changing the game. Future rapid prototyping technologies will allow for the creation of functional electronic circuits directly onto 3D-printed objects. This convergence of electronics and rapid prototyping will lead to innovations in smart devices, IoT applications, and wearable technology.

On-Demand Manufacturing and Localized Production

The future of rapid prototyping will also witness a shift towards on-demand manufacturing and localized production. With advancements in digital communication and transportation, it will become increasingly viable to send digital design files across the globe instantly. Localized manufacturing hubs with advanced rapid prototyping technologies will bring these designs to life, reducing shipping times and costs.

Environmentally Sustainable Prototyping

Rapid prototyping will also adapt to become more eco-friendly as the world becomes more conscious of environmental concerns. The development of biodegradable and recycled materials for 3D printing and energy-efficient manufacturing processes will contribute to a greener approach to prototyping. CNC services from China and other countries will likely adopt greener practices, including optimizing material usage and recycling waste, to reduce their carbon footprint.

Augmented Reality (AR) in Prototyping

Augmented Reality (AR) is poised to play a transformative role in rapid prototyping. Designers and engineers can overlay virtual prototypes onto the physical world, allowing for real-time visualization and interaction with their designs. This immersive experience will lead to faster and more intuitive design iterations, fostering creativity and innovation.

Conclusion

The future of rapid prototyping is filled with exciting possibilities driven by emerging technologies and novel applications. CNC services from China have already demonstrated their importance in this field, and their continued advancements will undoubtedly shape the industry further. As 3D printing, CNC machining, integrated software solutions, electronics prototyping, on-demand manufacturing, and augmented reality converge, the world of product development will witness a new era of efficiency, accessibility, and sustainability. Embracing these technologies and staying at the forefront of innovation will be crucial for businesses and designers seeking to thrive in the rapidly evolving landscape of rapid prototyping.