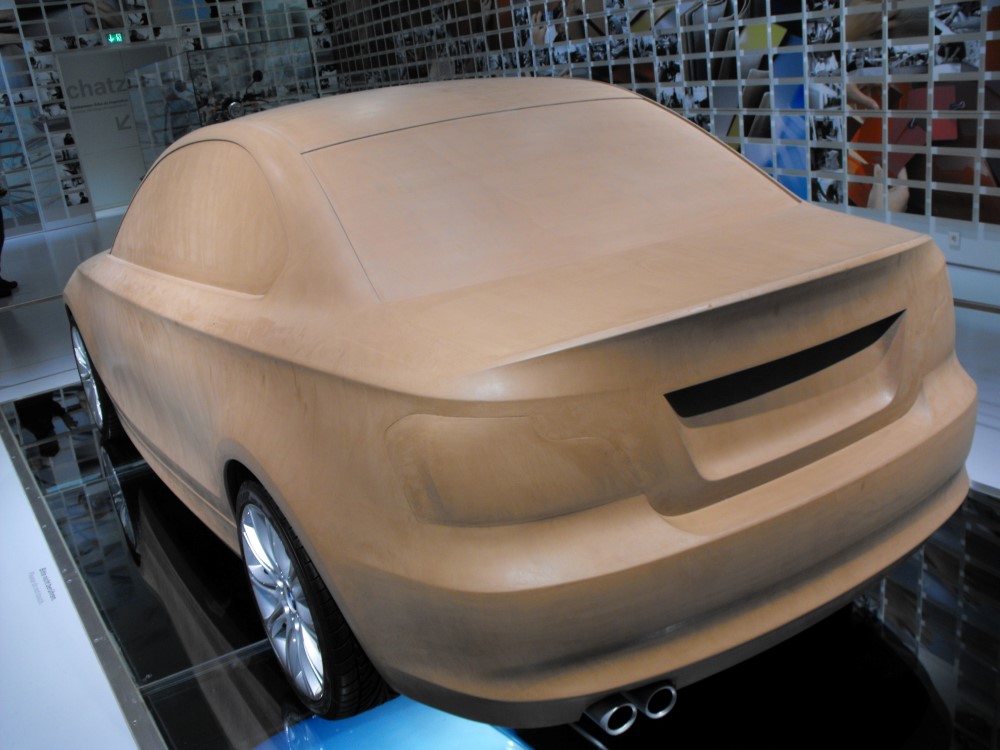

Digital Modeling and Fabrication is a plan and generation process that joins 3D displaying or figuring helped outline (CAD) with other substance and subtractive assembling. Added substance fabricating is otherwise called 3D printing, while subtractive assembling may likewise be referred to as machining and numerous different advancements can be used to physically deliver the planned for items.

Machine design takes into account various factors like how kinetics and kinematics can impede its control of energy or motion. Basically, you will have to implore a specified process which gives guidelines for machine design.

Before you finally manufacture a machine, you have to align to steps in machine design. Besides the basic steps you have to get on the ground and benchmark, determine the purpose of your machine, setting goals and brainstorming as well as creating a prototype and testing it. Digital machining takes a refined approach with new metrics.

Fabrication

Carefully manufactured items are made with an assortment of CAD programming bundles, utilizing both 2D vector drawing, and 3D demonstrating. Kinds of 3D models incorporate four models wireframe, strong, surface and work. A plan is having at least one of these model types.

Machines for fabrication

Three fabrication machines well known for manufacture:

- CNC Router

- Laser shaper

- 3D Printer

-

CNC Router

CNC stands for Computer Numerical Control. CNC factories or switches incorporate exclusive programming which translates 2D vector illustrations or 3D models and changes over this data to a G-code, which speaks to particular CNC works in alphanumeric configuration which the CNC plant can decipher.

CNC machines usually have a G-code. G-codes are any words in a CNC program which begin with the letter G. This code tells the CNC machine what type of action to perform and it makes them more relative to CNC technology.

As a result, CNC machines are able to conduct movement rapidly in between cuts. With automation they can also send controlled feed in an arc. Such fabrication machines are mills, lathes, drilling machines and plasma cutters.

The G-codes drive a machine device, a fueled mechanical gadget ordinarily used to manufacture components. CNC machines are ordered by the quantity of tomahawks that they have, with 3, 4 and 5 hub machines all being normal and modern robots being portrayed with having upwards of 9 axes.

Civilization has scaled its way past human labor. In big companies you are bound to find machine workers outnumbering human labor. The essence of this is to increase work output and it is all held together by Computer Numerical Control (CNC).

CNC systems are automated and this trademark has brought about an alliance with computers that program sequences for processing equipment and machine tools. While CNC was overly a manufacturing venture when it was first discovered, it has slowly found its way into the processing arena.

CNC machines are particularly fruitful in processing materials, for example, plywood, plastics, froth board, and metal at a quick speed. CNC machine beds are typically suitably broad to allow 4′ × 8′ (123 cm x 246 cm) sheets of material, including froth a few inches thick, to be cut.

-

Laser cutter

The laser cutter is a machine that uses a laser to cut materials, for example, chip board, matter board, felt, wood, and acrylic up to 3/8 inch;1 cm thickness. The laser shaper is frequently packaged with a driver programming which deciphers vector illustrations created by any number of CAD programming stages.

The laser shaper can balance the speed of the laser head, and also the force and determination of the laser shaft, and accordingly is capable in both to slice and to score material, and also estimated raster graphics. Articles cut out of materials can be utilized as a part of the creation of physical models, which will just require the get together of the level parts.

-

3D Printers

3D printers utilize an assortment of techniques and innovation to gather physical renditions of computerized objects. Ordinarily work area 3D printers can make little plastic 3D objects. They utilize a move of thin plastic fiber, liquefying the plastic and after that saving it unequivocally to cool and solidify. They typically fabricate 3D objects from base to top in a progression of numerous thin plastic flat layers. This procedure frequently occurs throughout a few hours.

Intertwined Digital Modeling

Intertwined digital displaying, otherwise called combined fiber manufacture, utilizes a 3-pivot automated framework that expels material, ordinarily a thermoplastic, one thin layer at any given moment and logically develops a shape. Cases of machines that utilization this strategy are the Dimension 768 and the Ultimaker.

Stereolithography

Stereolithography utilizes a high force light projector, more often than not utilizing DLP innovation, with a photosensitive polymer sap. It will extend the profile of a protest fabricate a solitary layer, curing the gum into a strong shape.

At that point the printer will move the question off the well-trodden path by a little sum and task the profile of the following layer. Cases of gadgets that utilization this technique are the Form-One printer and Os-RC Ill iOS.

Specific Laser Sintering

The specific laser sintering utilizes a laser to follow out the state of a question in a bed of finely powdered material that can be combined by utilization of warmth from the laser. After one layer has been followed by a laser, the overnight boardinghouse completed part is moved off the well-trodden path, a thin layer of the powdered material is spread, and the procedure is rehashed.

Run of the mill materials utilized are alumide, steel, glass, thermoplastics (particularly nylon), and certain pottery. Case gadgets incorporate the Formica P 110 and the Eos EosINT P730.

Powder Printer

Powder printers work in a comparable way to SLS machines, and ordinarily utilize powders that can be cured, solidified, or generally made strong by the utilization of a fluid cover that is conveyed by means of an inkjet print head.

Ordinary materials obtain mortar of Paris, dirt, powdered sugar, wood-filler holding putty, and flour, which are commonly cured with water, liquor, vinegar, or some blend thereof. The real preferred standpoint of powder and SLS machines is their capacity to ceaselessly bolster all parts of their articles all through the printing procedure with unprinted powder.

This allows the generation of geometries not effortlessly generally made. Nonetheless, these printers are frequently more perplexing and costly. Cases of printers utilizing this strategy are the ZCorp Zprint 400 and 450.